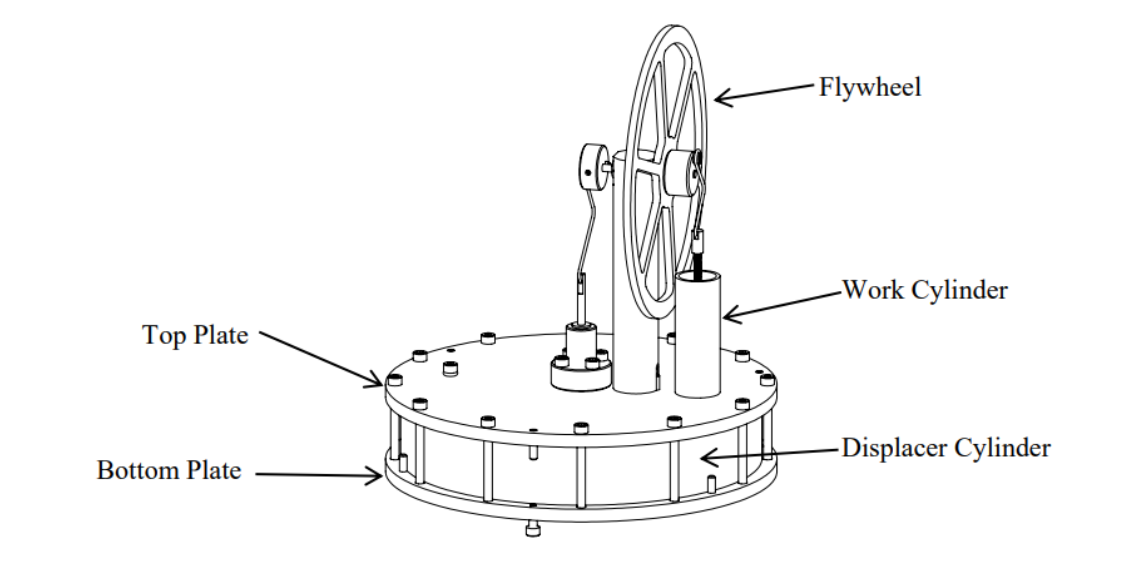

Gamma Configuration Stirling Engine

Redesign and fabrication of Gamma configuration Stirling Engine running on a 20C temperature differential.

For the ME 449: Redesign and Prototype Fabrication final project, my classmate (Josh Richlen) and I fabricated and redesigned a Gamma configuration Stirling engine. The fabrication of the baseline engine was done to get acquainted with using manufacturing methods, such as: mills, lathes, CNC controllers, and Waterjet cutting. The redesign was done to improve the baseline design based on the needs of our key stakeholders.

At the end of the course, there was a competition based on speed, aesthetics, and build quality. Our team got the highest speed improvement of 175% as well as the highest aesthetics and build quality scores. Our baseline engine ran at 77 RPM while our redesigned ran at 212 RPM, both at the same temperature difference of 20C.

Our slides can be found here here, the report can be found here, and a video demonstration during the day of the competition can be found here.